Boilers are widely employed in various industries, from power generation to chemical processing and heating applications. Like many other industrial goods used in such processes, it’s important the boiler you source meets industry regulations, safety standards, and performance benchmarks. Improper boiler fabrication and assembly can not only decrease efficiency but also pose significant safety risks.

To counteract these risks, companies frequently use third-party inspection services before shipment. These independent industrial boiler inspections evaluate and verifies whether the boilers adhere to the defined product specifications and quality standards.

In this article, we’ll take a look into the primary checkpoints that a third-party vendor, like us at AQM BD, uses when inspecting a boiler at the factory prior to the shipment.

Why Is Third Party Boiler Inspection Required?

The intricate nature of boiler design and construction demands a high level of precision and compliance with standards. Boilers, in essence, are very complex systems with stringent tolerances and material requirements due to their exposure to high pressures and temperatures.

A minor discrepancy in material composition, welding integrity or component assembly can have significant operational repercussions. Additionally, the specifications of boiler pressure parts, drum internals or safety components can differ depending on the manufacturer’s expertise and the regional standards they follow.

Third-party inspectors provide an unbiased evaluation of the overall boiler, ensuring the boilers you source align with your quality standards and safety regulations.

Third Party Boiler Inspection Checklist

AQM BD has decades of expertise in boiler inspection services and tank inspections, whether on-site for industries such as power generation or directly at the manufacturer’s premises. Although the third-party boiler inspection checklist outlined in this article provides a foundational understanding, it’s important to recognise that the inspection criteria and the boiler inspection procedure might vary based on individual circumstances.

Here’s a closer look at our approach:

1. Quantity Verification

Typically, the boiler inspection at the factory is undertaken at the pre-shipment stage. The inspector verifies that the complete set of products aligns with the purchase order.

2. Document Review

All relevant documentation, such as quality certification documents, boiler quality certificates, and test reports, are checked by the inspector.

3. Visual Check and Assembly Inspection

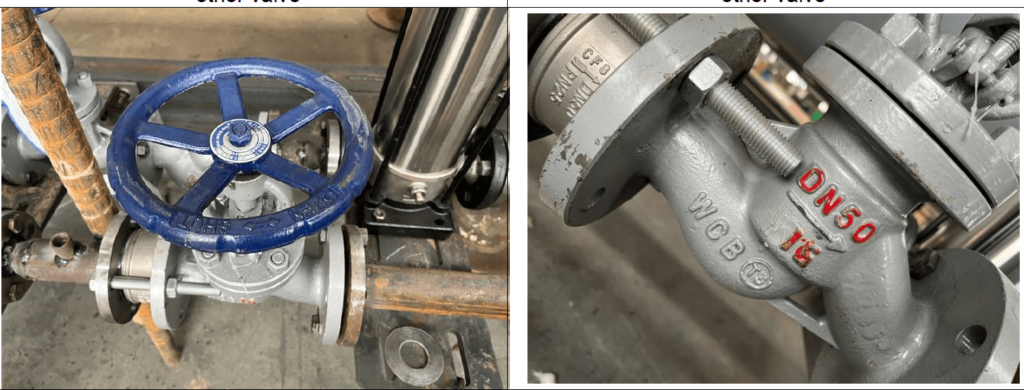

Inspectors assess the boiler’s craftsmanship, beginning with a visual review. For example, in the scenario we show in this article, the inspector inspected the firetube waste heat boiler’s weld seams, ensuring their uniformity and robustness. The main frame of components undergone an anti-corrosion check, and the inspector verified that valves and other equipment were accurately identified and tagged.

Some issues noted by our inspector include:

- Incomplete anti-corrosion treatment of certain pipes.

- Factory’s refusal to unveil the electrical PLC control panel package.

- Rust detected on a flange.

- Delay in the painting process.

The inspector checked that components and equipment were securely packed in wooden boxes for transit.

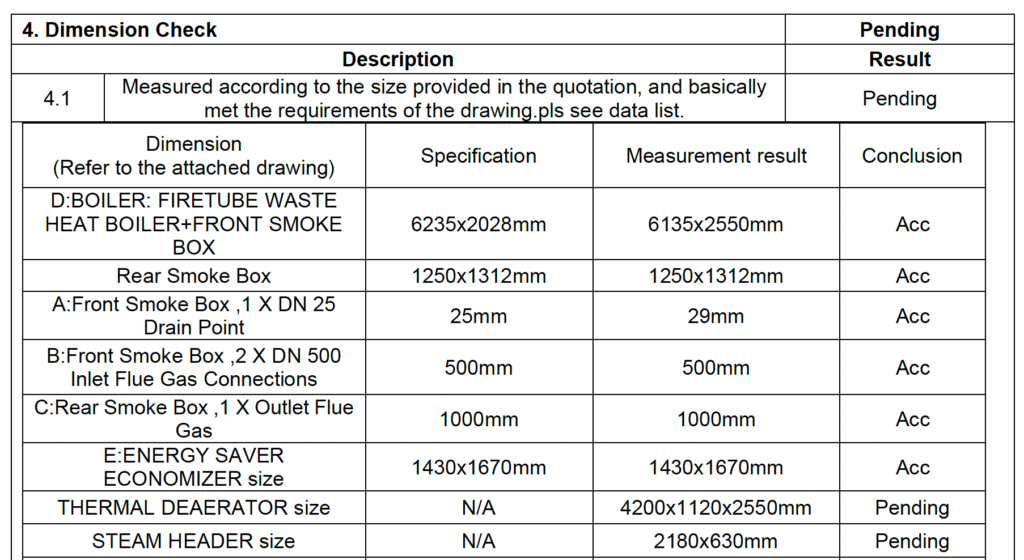

4. Boiler Dimension Verification

The inspectors employ precision-calibrated instruments, such as rulers, to confirm the boiler’s dimensions and alignment with set requirements. Any variances or deviations from the established tolerance levels are documented.

5. Performance Check

The boiler’s expected performance is gauged by either observing the factory conducting a test (FAT Witness Test) or verifying the factory’s pressure test report to ensure it adheres to the specified standards.

Conclusion

Due to the nature of boiler design and assembly, it’s important to verify boiler quality at the factory. An industrial boiler inspection comprises of quantity verification, documentation review, visual checks, dimension verification, and performance evaluations.

It’s worth noting that the boiler inspection checklist might differ on a case-by-case basis. At AQM BD, we offer unbiased third-party inspections for boilers and tanks. Whether you require a boiler inspection on-site or at factories in Vietnam, China, or India, contact us today to learn more about our services or if you have any queries.